Submersible drilling pumps (NORYL Turbines)

Turbines NORYL

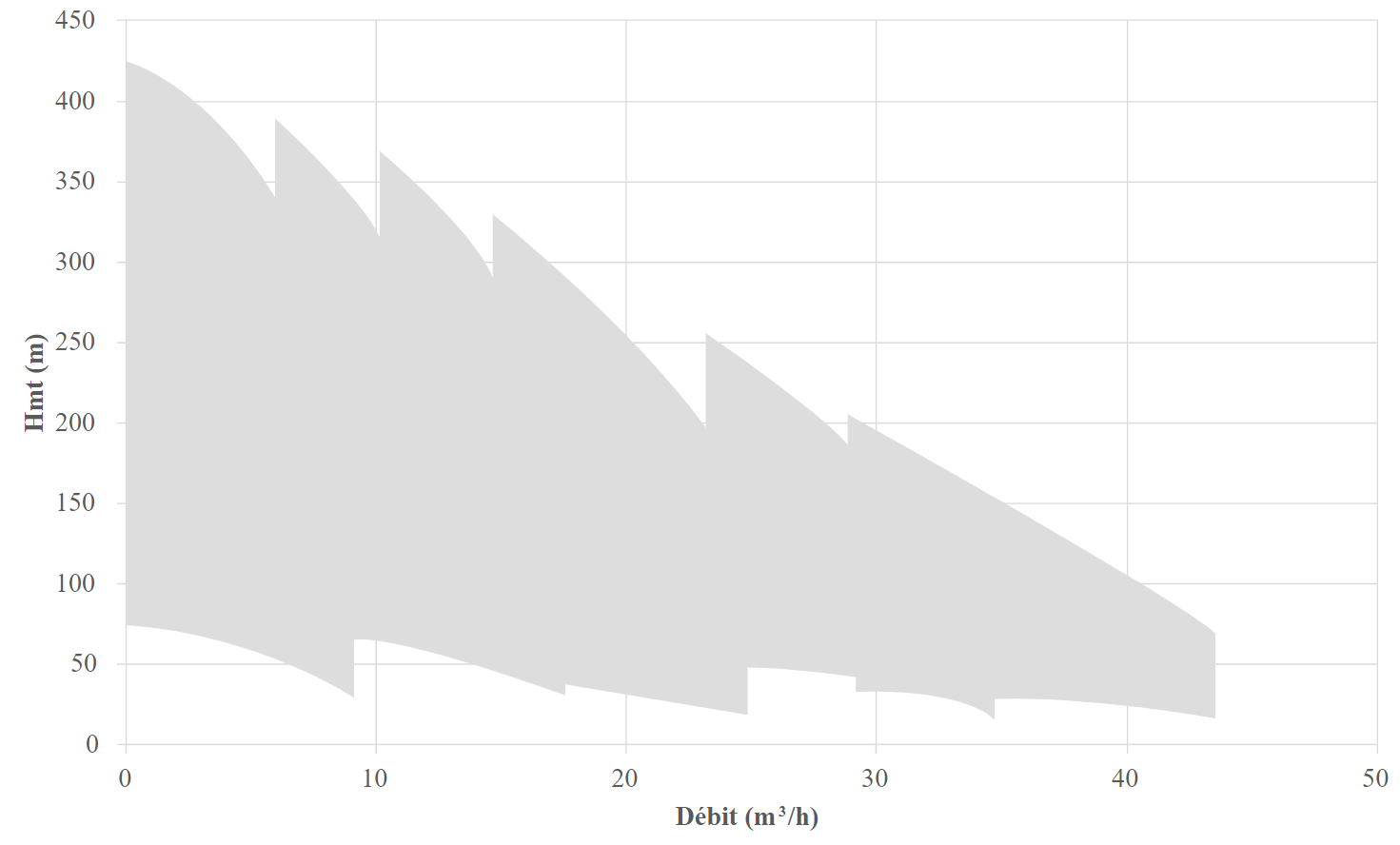

- Débit max. : 60 m³/h

- Hmt max. : 466 m

Submersible pumps for high pressures and flow rates, particularly equipped with a high rigidity silicon carbide (SIC) bearing, guarantee reliability and quality.